In a world where humans are still struggling to find their keys, robotic arms are stepping up to save the day—one precise movement at a time. These remarkable machines don’t just look cool; they’re revolutionizing industries from manufacturing to healthcare. Imagine a robotic arm expertly assembling your favorite gadget while you sip coffee and binge-watch cat videos. Now that’s multitasking at its finest!

Table of Contents

ToggleOverview of Robotic Arms

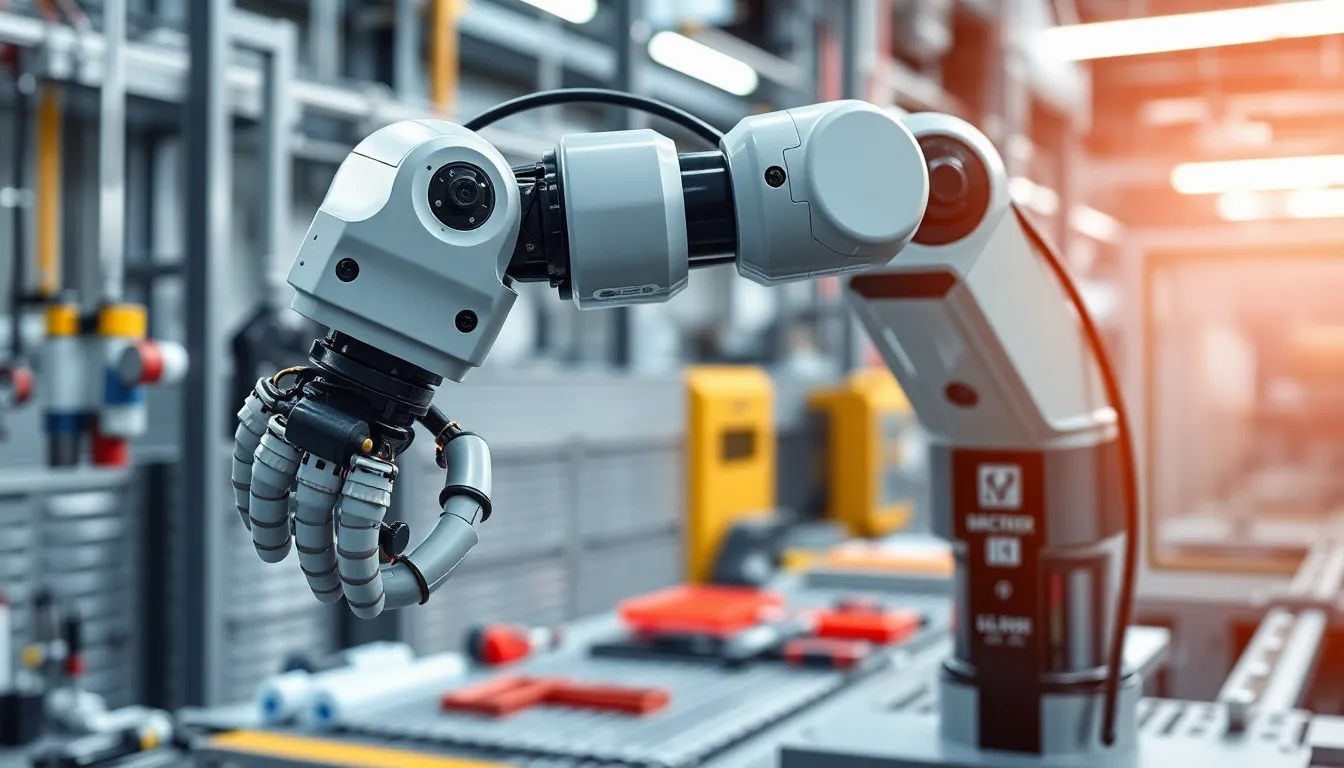

Robotic arms represent a significant advancement in automation technology. Used in various sectors, these devices excel in performing repetitive tasks with speed and accuracy. Industries rely on robotic arms for assembly lines, where consistency and precision are critical for product quality.

Adaptable in design, robotic arms can take on diverse roles, from welding to packaging. Their ability to operate in challenging environments, such as extreme temperatures and hazardous conditions, enhances their value. Many manufacturing plants integrate these machines to boost productivity and reduce human error.

Flexibility is a key feature of robotic arms. Designers configure them with different end effectors, allowing them to grip, lift, or manipulate objects in various shapes and sizes. This customization enables robotic arms to work efficiently across multiple applications.

Safety protocols govern the use of robotic arms. These machines often include sensors to detect nearby personnel, reducing the likelihood of accidents. Consequently, employers value the improved safety measures robotic arms bring to workplaces.

Growth in the healthcare sector also highlights the relevance of robotic arms. Surgeons utilize robotic-assisted systems for intricate procedures, enhancing precision during operations. This technology not only improves outcomes but also shortens recovery times for patients.

Cost-effectiveness serves as another advantage of robotic arms. Despite high initial investment costs, long-term savings through increased efficiency and reduced labor costs justify their purchase. Many businesses find that robotic arms contribute to a positive return on investment.

Adoption rates continue to climb as industries recognize the benefits. Companies are increasingly exploring the potential of robotic arms to transform business processes and optimize production capabilities. The future points toward an expansion of their role in both manufacturing and service sectors.

Types of Robotic Arms

Robotic arms come in various types, each serving distinct purposes across industries. Understanding these types helps in selecting the right arm for specific tasks.

Industrial Robotic Arms

Industrial robotic arms excel in manufacturing environments. These robots specialize in repetitive tasks like welding, painting, and assembly. Typically, they feature a fixed configuration that maximizes reach and precision. Manufacturers often choose six-axis robotic arms for their versatility and flexibility in handling complex tasks. Capable of lifting heavy loads, they significantly improve production efficiency. Integration into assembly lines leads to consistent output, enhancing overall quality.

Collaborative Robotic Arms

Collaborative robotic arms, also known as cobots, work alongside human operators. These robots feature safety protocols, allowing for safe interaction in shared spaces. Often lighter and smaller, cobots can perform various tasks like assembly or packaging without the need for extensive safety barriers. Their design emphasizes ease of use, enabling fast deployment across different operations. Businesses increasingly adopt collaborative arms due to their ability to enhance productivity while maintaining a safe working environment.

Key Features and Technologies

Robotic arms incorporate advanced technologies that enhance their capabilities in various applications. Key components include sensors, feedback systems, actuators, and motion control mechanisms.

Sensors and Feedback Systems

Sensors play a crucial role in robotic arms, allowing them to interact with their environment effectively. They can detect position, orientation, and touch with high precision. Feedback systems, on the other hand, provide real-time data to control mechanisms. This data helps ensure accurate movements. For instance, force sensors enable the robotic arm to adjust pressure while gripping objects, preventing damage during handling. Proximity sensors enhance safety by detecting nearby personnel and halting operations when necessary. Ultimately, these technologies contribute to greater efficiency and improved performance in sectors like manufacturing and healthcare.

Actuators and Motion Control

Actuators are essential for translating electrical signals into motion. They drive the robotic arm’s joints, facilitating precise movements. Several types of actuators exist, including electric, pneumatic, and hydraulic systems, each offering different advantages based on the task. Motion control algorithms coordinate these actuators, allowing for smooth and accurate positioning. Systems can execute complex trajectories, enabling tasks like welding, painting, and assembly. High-level control methods optimize these movements, ensuring energy efficiency and enhanced productivity. Together, actuators and motion control technologies significantly enhance the capabilities of robotic arms across various industries.

Applications of Robotic Arms

Robotic arms find numerous applications across various industries, significantly boosting productivity and precision.

Manufacturing and Assembly

In manufacturing and assembly, robotic arms play a critical role in enhancing efficiency. Companies utilize them for tasks like welding, painting, and parts assembly. Their ability to handle heavy loads and perform with high precision leads to improved product quality. Many industrial robotic arms feature six-axis designs that facilitate complex movements. Additionally, these robots operate without fatigue, allowing for continuous production cycles. Adaptability is another advantage, as manufacturers can program robotic arms for different tasks based on needs. The overall reduction in operational costs results from fewer errors and decreased labor requirements.

Medical and Surgical Uses

Robotic arms increasingly revolutionize medical and surgical fields, improving patient outcomes. Surgeons employ robotic-assisted systems for intricate procedures, where precision is paramount. Enhanced visualization and dexterity allow for minimally invasive techniques. Many robotic platforms provide surgeons with superior control, reducing recovery times. Their applications extend from orthopedic surgeries to complicated cardiac procedures. Integration of robotic arms into medical workflows also improves safety for both patients and healthcare providers. Utilization of these advanced technologies underscores the ongoing shift towards automation in healthcare settings, streamlining complex processes for better service delivery.

Advantages and Disadvantages

Robotic arms come with significant advantages and certain limitations that affect their implementation across industries.

Benefits of Robotic Arms

Efficiency stands out as a major benefit of robotic arms, enabling rapid execution of tasks without delays. Precision enhances product quality, particularly in manufacturing, where slight errors can lead to costly defects. Adaptability also plays a role; robotic arms can be outfitted with various tools to complete diverse tasks, allowing for flexibility in production. Safety improves in environments where hazardous materials exist, as robots can handle dangerous processes without risking human injury. Labor costs decrease with automation; although initial investments are high, long-term savings contribute to an attractive return on investment.

Limitations and Challenges

High initial costs represent a significant barrier that many businesses face when adopting robotic arms. Integration with existing systems can pose challenges, often requiring adjustments to current workflows and equipment. Training staff to operate and maintain robotic arms adds another layer of complexity; skilled technicians are necessary for optimal use. Limited capabilities also exist for certain tasks, particularly those requiring intricate human intuition or decision-making. Additionally, maintenance and potential downtime can disrupt operations and incur unexpected expenses.

Robotic arms are undeniably shaping the future of various industries by enhancing efficiency and precision. Their adaptability allows them to tackle a wide range of tasks while improving workplace safety and reducing operational costs. As technology continues to evolve, the integration of advanced sensors and motion control systems will further elevate the capabilities of these machines.

While challenges remain in terms of initial investment and integration, the long-term benefits clearly outweigh the drawbacks. Industries are increasingly recognizing the value of robotic arms, leading to higher adoption rates. This trend signals a promising future where robotic arms will play a pivotal role in both manufacturing and healthcare, ultimately transforming how work is conducted across multiple sectors.